AutoStore

- 70% increase in storage capacity without expanding the footprint,

- 4x faster warehouse processes,

- 99.8%+ availability,

- automated solution,

these are the main features of AUTOSTORE.

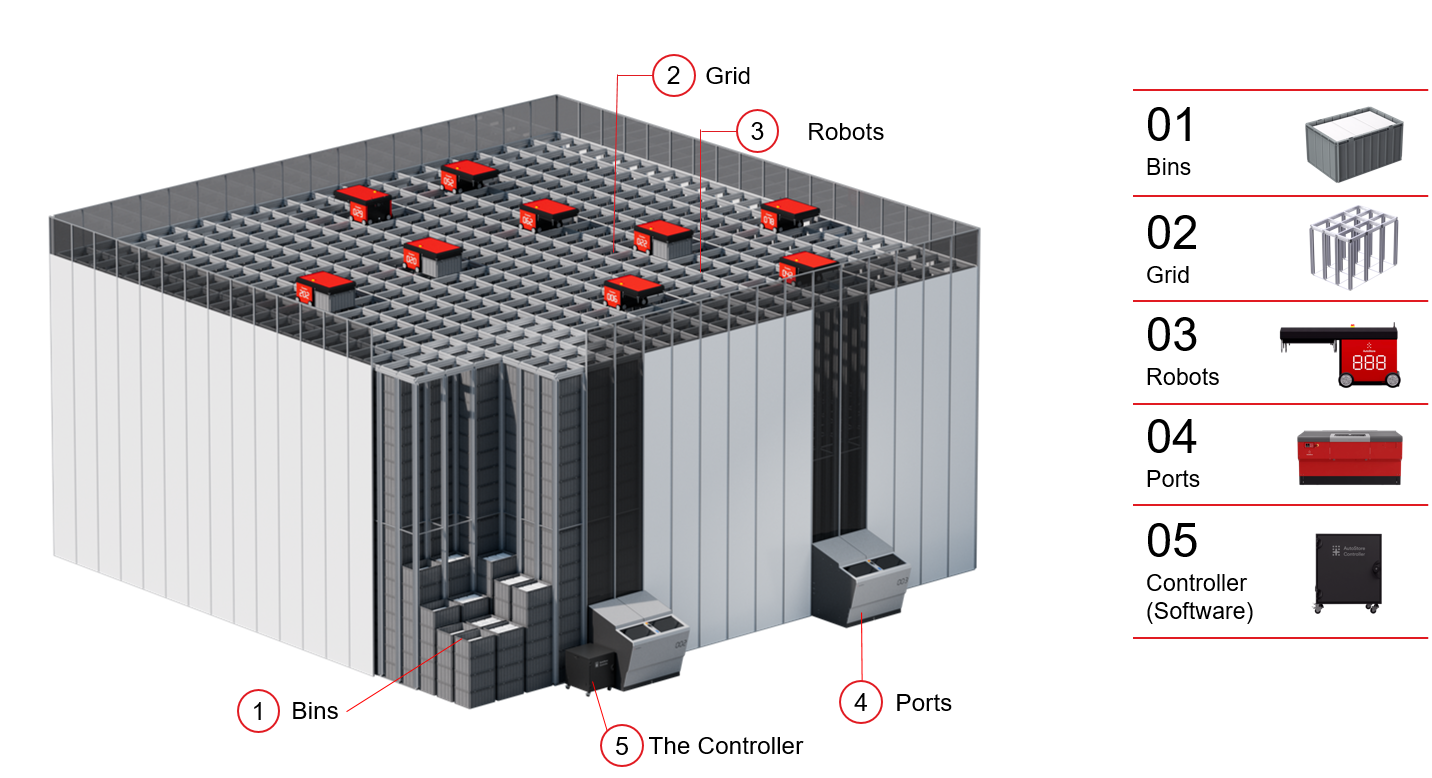

The essence of AutoStore technology is a cube-based storage solution. It is flexibly customizable and modular, with robots running on top of the storage system performing warehouse operations.

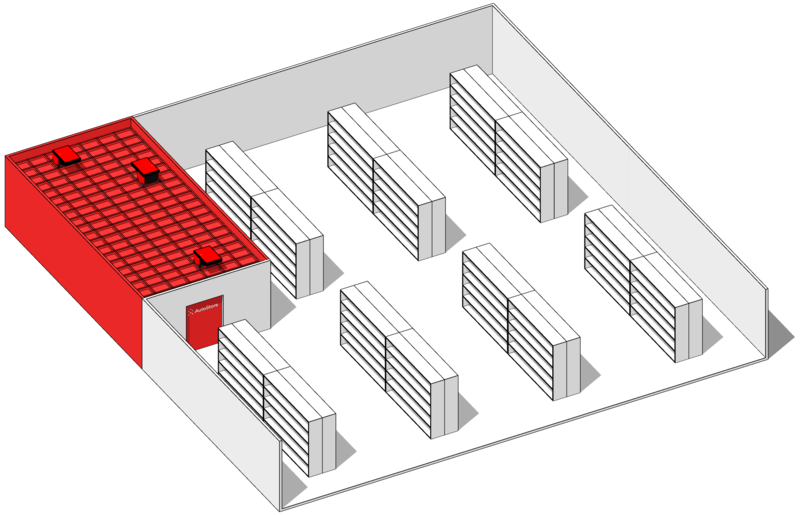

The AutoStore storage layout ensures the density of goods that allows for a 75% savings in warehouse floor space without building expansion:

The figure above clearly illustrates AutoStore's efficient use of floor space. The familiar static storage method is shown in white, while the same capacity stored using AutoStore technology is shown in red, requiring significantly less warehouse floor space.

Tip: Save hundreds of millions or even billions by examining storage technology options before expanding your building! Nowadays, increasing storage capacity does NOT start with expanding the building. Yet many companies still make this mistake!

Only very "wealthy" companies can afford this, as the construction costs of industrial buildings far exceed the costs associated with AutoStore technology.

To learn more about the additional benefits of the AustoStore system, take a look at its main components:

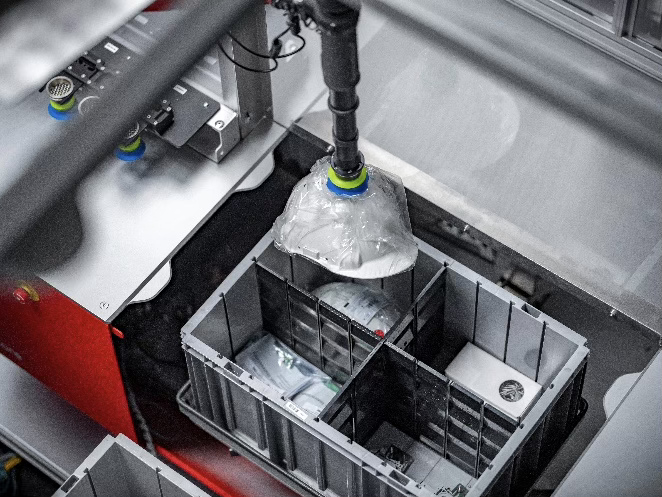

The storage density provided by AutoStore is ensured by the bins stored in the system.

It is important to note that a given bin can be divided into thirty-two separate compartments. This allows different types of items to be safely separated from each other in an AutoStore bin.

The stability of the bins and the path of the robots is ensured by an aluminum grid structure. Within the grid structure, AutoStore bins are stacked on top of each other using a block storage method, ensuring that they are secure.

The question rightly arises:

Thanks to the AutoStore robot system, retrieving the bottom crate from the system takes only 3.5 to 4 minutes.

It is also important to note that AutoStore places higher turnover items at the top of the array and slower turnover items at the bottom, and is able to prepare the bins for retrieval, thus reducing retrieval time.

Did you know? How much time difference is there between picking fast- and slow-moving items in your current storage system and picking times in AutoStore?

Based on our experience and manufacturer case studies, AutoStore enables four times faster picking.

One of the most important factors for robots is energy efficiency.

Ten AutoStore robots consume the same amount of energy as a household vacuum cleaner.

The AutoStore robot control program ensures efficient route optimization for the robots and enables them to work as a team.

Goods are stored and retrieved from AutoStore systems via ports.

Both cost-effectiveness and workflow efficiency depend largely on the selection of the appropriate port.

There are several ports with different functions available for AutoStore systems.

The most suitable solution can be selected based on the tasks, functions, nature, and throughput time associated with the ports.

The development team at AutoStore's parent company in Norway supports companies interested in or already committed to AutoStore technology with increasingly modern solutions every year.

These include:

Zenit Kft.'s relationship with AutoStore technology goes back more than three years.

How have these three years been?

We provide our customers with a comprehensive service package, from design to maintenance.

We have formed a team of technicians with Grid construction certification.

We have completed 5 successful AutoStore installation projects in Hungary.

We have developed a continuously available maintenance service.

Our highly skilled professionals install and maintain AutoStore systems in compliance with all occupational safety regulations.

Just as dishwashers were once a rarity but are now found in almost every household, AutoStore will become an integral part of every warehouse.

Don't let your competitors get there first!

If you would like more information about AutoStore technology and development opportunities, please contact us at any of our contact details, or simply fill out the quote request form below:

How long does it take to reach the bottom bin?

Robots

Ports

Developments are ongoing

AutoStore technology through Zenit Kft.